Empowering IGU Production: Smart MES Meets Warm Edge Technology

As Hanjiang continues to engage deeply with hundreds of smart factory projects, we have come to a clear realization: among all units in architectural glass deep processing, the insulating glass (IG) production line consistently demands the most manpower.

Take the 2021 automation project by MAC-YUGONG for BOYU,CHINA as an example. A single shift requires the following personnel: 1 person for raw glass storage, 1–2 for cutting, 1 for edging, 2 for the tempering furnace, 5 for the IG line, and 4 for the laminating line. In total, an intelligent factory needs around 15 people per shift.

If this comparison is not compelling enough, consider the 2023 automation project MAC-YUGONG executed for FUTENG, CHINA. This factory is equipped with two smart processing lines and four IG lines. Under a two-shift operation, the cutting-edging-tempering unit requires 20 people, while the IG lines demand nearly 50 people (4 lines × 6 people × 2 shifts, plus 2 IG production managers).

This clearly highlights that the IG production unit remains a critical bottleneck in the pursuit of full automation and smart manufacturing.

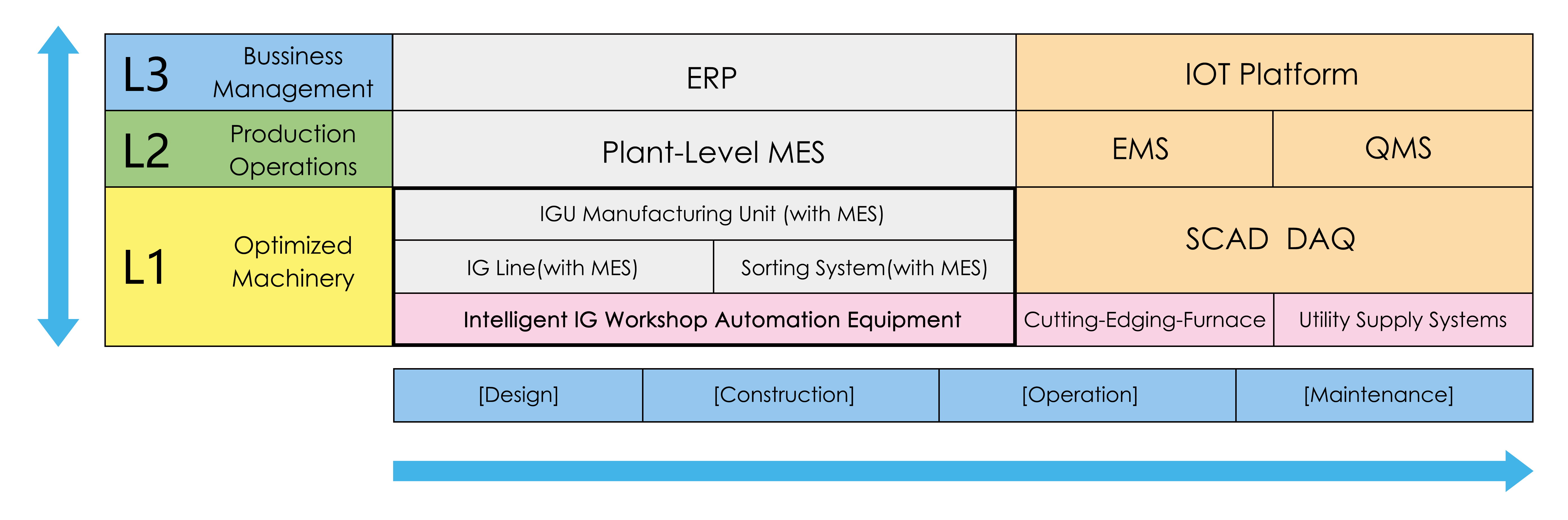

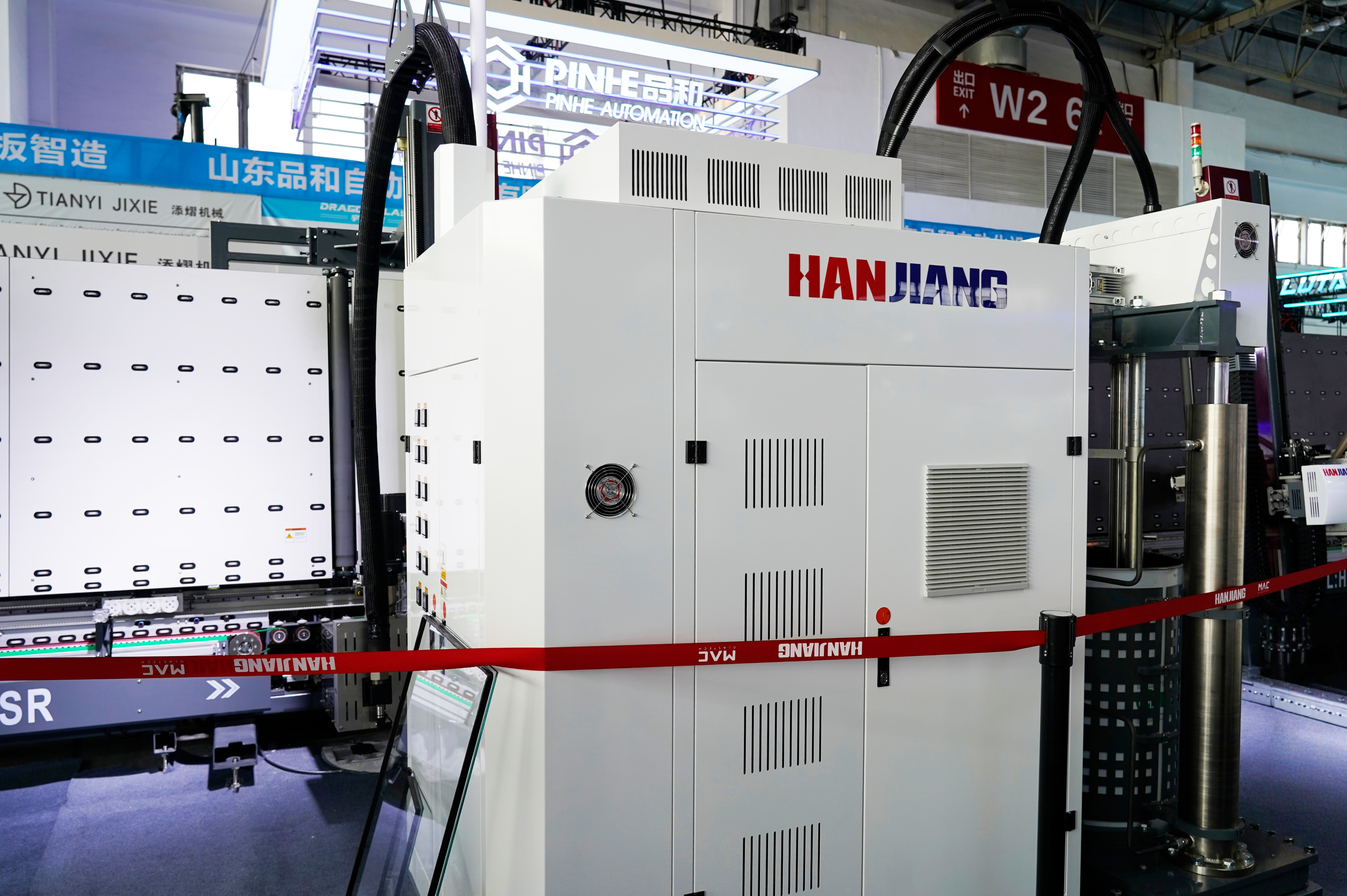

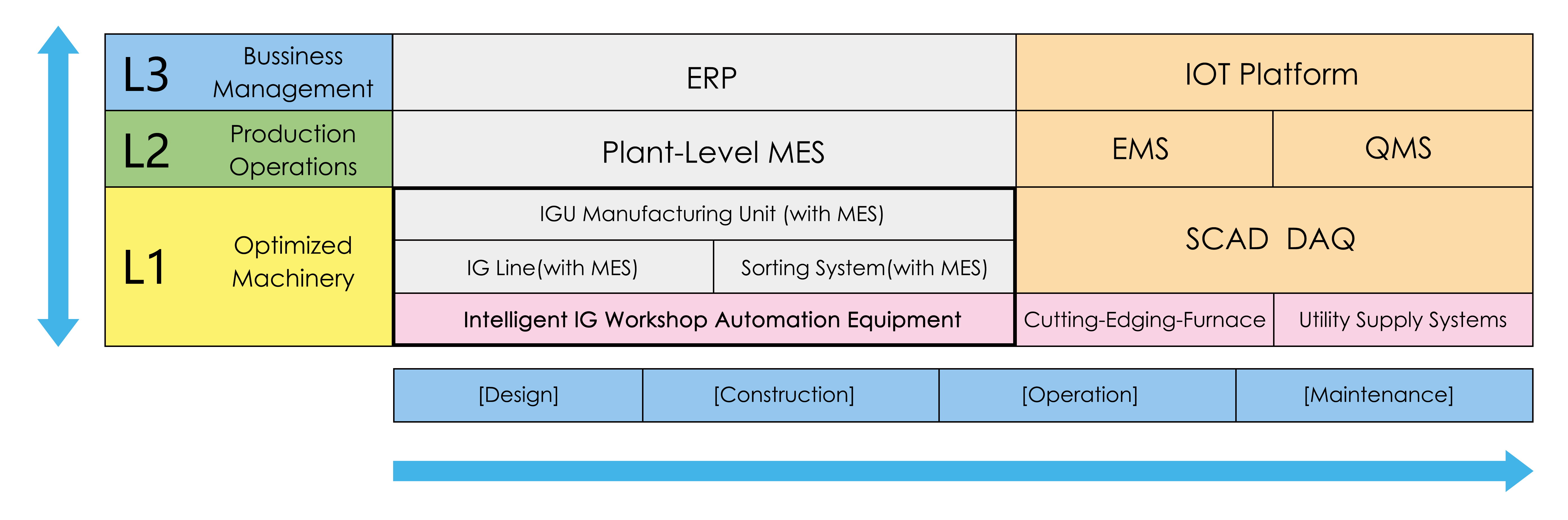

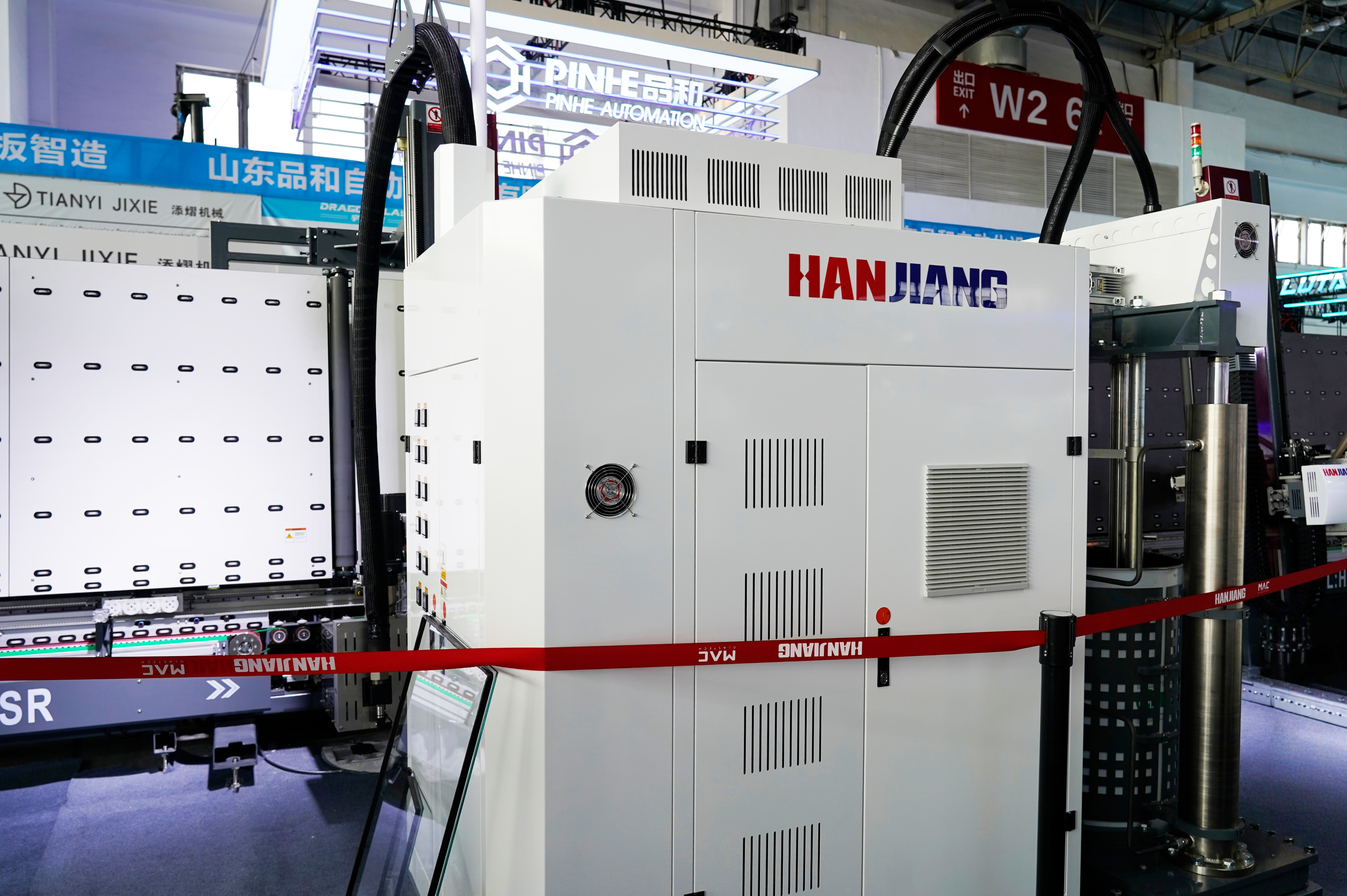

As automation continues to mature in the glass deep-processing industry, a key question emerges: how can manufacturers adopt a minimal-labor model while truly achieving cost reduction, efficiency gains, and quality control in IG production units? This has been the core focus of Hanjiang’s research over the past three years. At the 2025 China Glass Expo, Hanjiang successfully showcased a fully integrated production chain—from ERP order placement to MES work scheduling to intelligent IGU manufacturing cells—marking a significant milestone in the realization of smart insulating glass production.

At this exhibition, all products—from ERP and MES to the IGU manufacturing unit, spanning software to hardware—were independently developed by our group companies.

The MAC-YUGONG ERP enables one-click order placement for IGU production. Unlike conventional ERPs used in normal glass factories, our system integrates all technical specifications for IGU production right from the order entry stage. This includes detailed configurations for Glass A such as glass type, surface treatment (e.g., printing, sandblasting), thickness, manufacturer, and processing flow (cutting, grinding/polishing, Low-E edge deletion, tempering, IGU, lamination). It also defines spacer bar types like aluminum, Super Spacer, TPS, spacer width, sealant depth, and whether gas filling is required. Glass B is configured in parallel. For shape glass or step glass, users can input dimensions or upload CAD drawings for customized ordering. This creates a truly integrated and digitalized IGU ordering workflow.

The clearer and more specific the information provided during ERP order placement, the easier it becomes for the MES system to interpret and execute, thus enabling true intelligent production. In this system, the ERP transmits production commands directly to the IG-level MES, which functions as the “digital production manager” of the IG line.

The MES communicates directly with various PLCs, treating each device with an independent control system as an individual PLC node. At the exhibition, the demonstrated production unit included: automatic loading table, compact vertical sorting system, 90° turing table, washing machine, visual inspection system (Line Eyes), Super-Spacer applicator, TSR, gas-filling press machine, automatic cork applicator, sealing robot, and automatic unloading station.

Once the MES receives the production orders for the day, the operator only need to select orders and to press “Start” and place the designated glass racks onto the automatic loading table. The system then automatically sends both clear and Low-E glass into the sorting system. Each piece is scanned by a CCD camera, and the associated QR code—which contains all information originally defined in the ERP order—is read and logged.

The sorting system intelligently groups glass into A/B pairs before sending them to the washing. For limited workshop spaces, our L-shaped or U-shaped layout options offer efficient alternatives. The glass then turns 90 degrees into a high-speed washing machine, equipped with pre-washing features. The washing machine supports large and thick glass panels, with thicknesses ranging from 3 mm to 25 mm.

The updated air knife significantly increases the drying speed to 10–12 meters per minute, enabling full-surface, dead-zone-free cleaning and high-efficiency drying across the entire washing machine.

For high-quality glass, inspection is a important step. The Line Eyes visual inspection system accommodates varying definitions of surface defects from different customers, accurately detecting all standard flaws.

Beyond the automated transmission of production orders, a core aspect of intelligent manufacturing is replacing manual operations with automation. Hanjiang’s displayed Super-spacer applicator and TSR provide a streamlined solution to replace the labor-intensive processes associated with conventional aluminum spacers—including spacer cutting/bending, desiccant filling, butyl adhesive, and manual frame mounting.

Upon receiving MES instructions, the system automatically identifies parameters such as spacer type (Super-spacer or TPS) and thickness, and completes the frame mounting process in a single operation. This transition from aluminum to warm-edge spacers not only reduces labor requirements but also greatly enhances the quality, performance and aesthetic quality of IGU.

The press machine intelligently works based on MES instruction including whether the IGU is double or triple-glazed, whether it is step glass, the specific dimensions of step, and whether gas filling is required. All processes are completed automatically and precisely.

Similarly, the sealing robot no longer requires manual input of spacer widths. It automatically interprets order information and switches between sealant supply system #1 or #2 accordingly, ensuring efficient and accurate sealing.

Once sealing is complete, the glass is smoothly transferred to the designated rack via the automatic unloading station.

This intelligent IGU production unit integrates ERP–MES–PLC data flow with fully automated machinery to provide a one-stop solution for handling complex and diverse IGU orders.

Ultimately, every smart factory revolves around three goals: cost reduction, efficiency improvement, and quality improvement. Whether or not you currently operate a smart factory, a highly intelligent IGU processing unit can empower you with true flexibility and autonomy in glass production.

The Hanjiang team is ready to help you unlock deeper insights into the “know-how” of smart IGU production.